SYNTEC Technology (7750-TW), Leantec Intelligent, and Jumbo Laser joined forces to showcase the latest metal processing technologies and smart, automated solutions at this year's Automation Exhibition. Among them, Jumbo Laser focuses on the demands of the new energy and electronics industries, laying out semiconductor microfabrication development. By integrating IIoT technologies, they have not only achieved intelligent interconnection but also effectively advanced their carbon reduction goals. Jumbo Laser's General Manager, Mr. Jacky Chen, shared a case with CSC (China Steel Corporation), in which AI smart manufacturing helped CSC reduce over 1,000 tons of carbon emissions annually, advancing toward a promising ESG future.

Jacky Chen explained that many current processing methods are contact-based, requiring high power—for example, CNC machines. If laser processing is adopted, which is a non-contact light-based method that focuses high energy for cutting or welding, the average power consumption is significantly lower, even up to half that of traditional processes achieving the same results.

On the environmental side, lasers greatly reduce pollution. In the past, etching required chemical agents, and inkjet techniques involved ink contamination. With laser technology, there’s no need to handle chemical waste anymore, which supports low-carbon and sustainable operations—an essential aspect of ESG’s environmental pillar.

From a corporate governance perspective, automation and intelligence reduce labor intensity, fostering a friendlier workplace—another key ESG focus.

Regarding AI applications, Chen explained: “We provide one-stop smart manufacturing solutions, essentially making machines smarter. Previously, automation involved arranging parts on the production line and having experienced operators inspect quality. With AI, the first step is machine learning—if a defect like a hole occurs during laser welding, instead of detecting it only at the end, AI can now self-adapt in real-time and detect problems on the line.”

The second step involves systematic parameter adjustment. For example, in a government-funded AI Robot project, after collecting extensive data, the system would adjust laser power accordingly and provide suggestions—similar to training employees.

As for successful AI manufacturing implementations, Chen cited CSC’s customer Kuozui Motors, a Toyota manufacturer. Previously, CSC used inkjet codes on steel coils, which Kuozui couldn’t use for car bodies, resulting in material cuts and costly remelting. Jumbo Laser provided a solution using vision systems to mark IDs directly on steel strips instead. This saved over 1,000 tons of CO₂ emissions annually, a successful real-world ESG case.

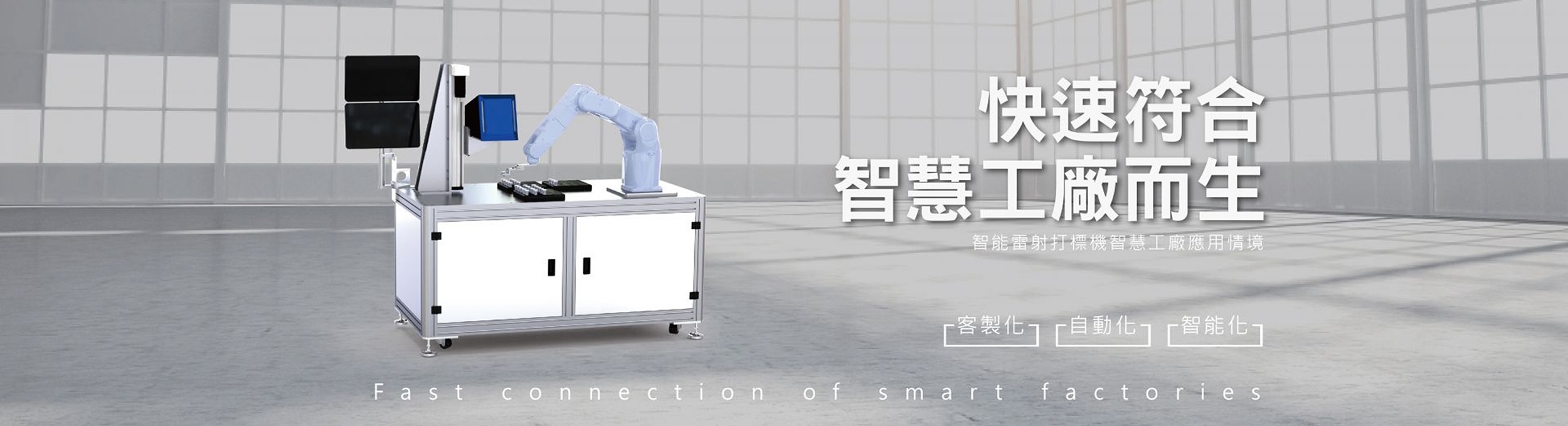

The second case involved Sanyang, a leading tripod manufacturer, which set up a smart factory in Douliu. They used to employ many migrant workers to manually load/unload heavy tripods. With 4–5,000 product types, five laser marking machines required 10 people. To reduce labor intensity, they developed a 3D vision-based laser marker using a Leantec robotic arm and Solomon's system to identify items and match them to a large database.

Customers benefit in two key ways: First, automation and intelligence via 3D vision modeling; second, aligning with ESG governance by reallocating workers from strenuous tasks to value-added roles like yield monitoring—supporting a happy, efficient workplace. Chen emphasized that SYNTEC Group’s solutions are closely tied to ESG values and growth with clients across industries such as electronics, metal processing, steel, automotive, golf heads, and hand tools. Each has unique needs and profit margins, so SYNTEC provides tailored solutions.

Regarding semiconductor market development, Chen explained that the industry is evolving in two directions: one toward advanced processes and packaging like TSMC, and the other toward third-gen semiconductors like SiC and GaN. While mainland China is advancing rapidly in the latter, most companies still rely on second-gen silicon. Entering this market is difficult and validation cycles are long.

Currently, semiconductor clients are limited, but peripheral players still require laser equipment and design. Recently, Jumbo Laser collaborated with ITRI on a wafer regeneration demolding solution. Previously, this relied on chemical or abrasive methods, generating waste. Now, laser surface removal is followed by precision mold application—still under development.