2025-03-17

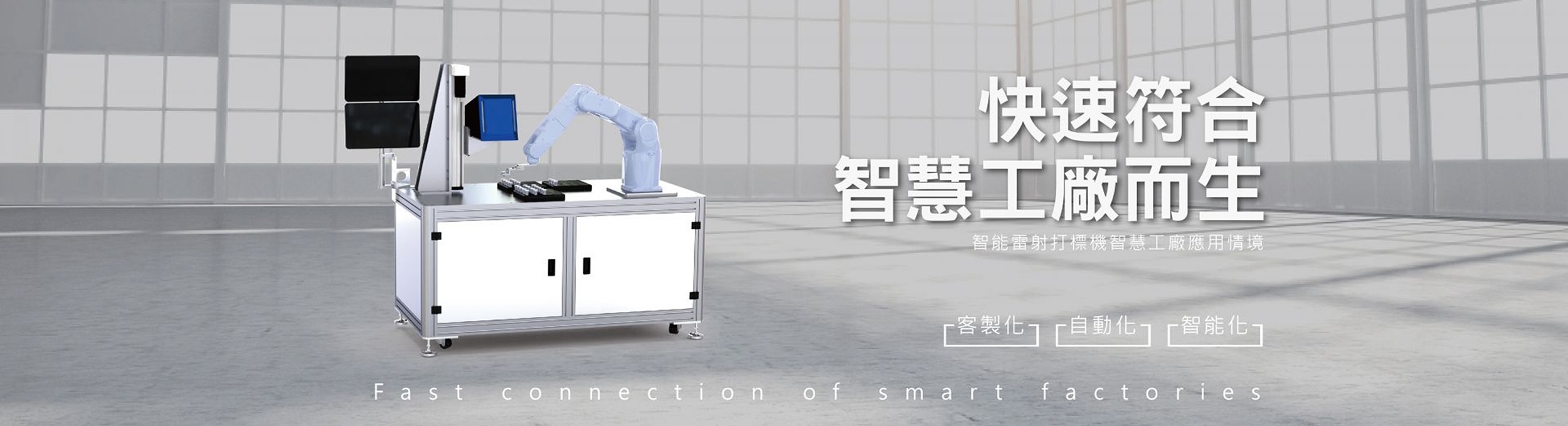

Taiwan's leading steel manufacturer, with an annual production capacity of 16 million tons. Amid the global ESG trend, the company is actively pursuing zero-carbon manufacturing processes. The effort begins with the indispensable production labeling on each steel coil. Maintaining stable production capacity and quality, the biggest challenge for the team is how to perform laser marking on large steel coils and integrate with automated peripheral operations.To prevent mixing products from different orders, the customer manually writes or uses inkjet printing to mark numbers on the outer surface of the steel coil. This approach causes two main issues: first, the use of ink consumables and periodic maintenance; second, ink markings are hard to remove. As a result, materials with steel coil numbers cannot be used directly by customers such as automotive or casing manufacturers. They often have to cut off the numbered area before usage, causing material loss and indirectly increasing overall material costs.With the assistance of the ZB Laser team, smart automation was introduced.SolutionThe current challenge is to reduce the size of the numbers and use laser marking on the steel coil straps instead.The steel coil number must be accurately positioned on a small area and on non-fixed positions of the strap; furthermore, laser marking must be performed on different straps. The proposed solution is to combine laser marking with a six-axis robotic arm for movement, assisted by an AI vision system, laser rangefinder, and other intelligent positioning systems, enabling precise and intelligent positioning of the laser marking machine to guide the correct engraving path.Laser marking offers advantages such as high speed, stable laser power, and long service life. It solves the steel coil material loss issue and is environmentally friendly with no pollution. Paired with the robotic arm, it eliminates the time-consuming manual alignment operations.By switching to laser marking for steel coil numbers, the ink pollution is eliminated and the steel coil material loss problem is resolved. The material yield of steel coils is greatly improved, helping the company save nearly ten million NTD annually, achieving zero pollution, waste reduction, and low cost in the manufacturing process.News report link → https://n.yam.com/Article/20231212155328