Currently, in industrial applications for metal laser welding, fiber lasers and YAG lasers with a wavelength of approximately 1064nm are mostly used. This is mainly because metals have excellent absorption rates at this laser wavelength, resulting in superior processing quality. Below is a brief explanation of the differences between fiber lasers and YAG lasers:

1. YAG Laser

A traditional solid-state laser, excited by optical pumping technology. It features stable energy output and lower cost, but requires regular replacement of the lamp and consumes more power.

2. Fiber Laser

Uses fiber optic transmission, is compact, highly stable, consumable-free, and has excellent beam quality. It is suitable for integration with automation equipment and is the current mainstream trend.

Figure 1: KUKA Laser Welding Robot at the 2018 Shanghai Industrial Expo

Laser Welding Robots

Robotic arms can perform multi-axis movements, combining lasers and vision modules for automated, precise welding. They are commonly used in automotive electronics, sheet metal, and hardware tool applications.

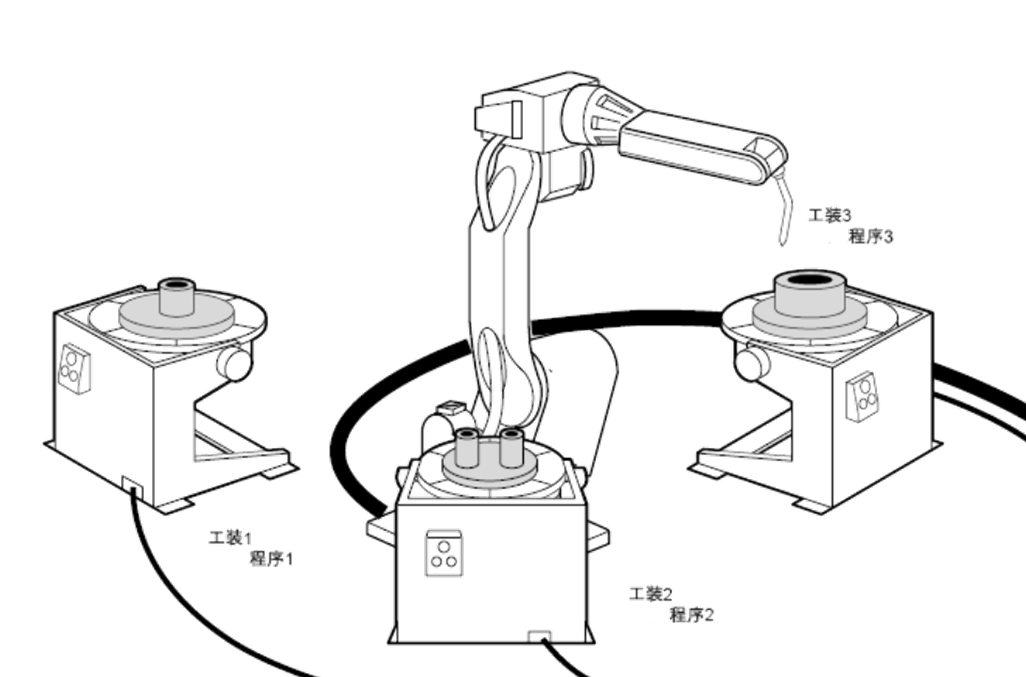

Figure 2: Laser Galvo Vision Positioning Welding Robot by Lian Da Intelligent Co.

Four-Axis Linked Laser Welding Technology

Four-axis refers to the X, Y, and Z axes plus a W-axis rotational axis, often controlled by servos, providing high precision and repeatable positioning. It is paired with a CCD camera focusing system, where a clear real-time image indicates the focal point.

This technology is suitable for thick plates, thin plates, and dissimilar material joining, enabling complex welding processes such as spot welding, butt welding, overlap welding, seam welding, and sealing welding.

Figure 3: Illustration of Four-Axis Linked Welding Application