To help you make the best choice, we need to understand your welding requirements in detail, including:

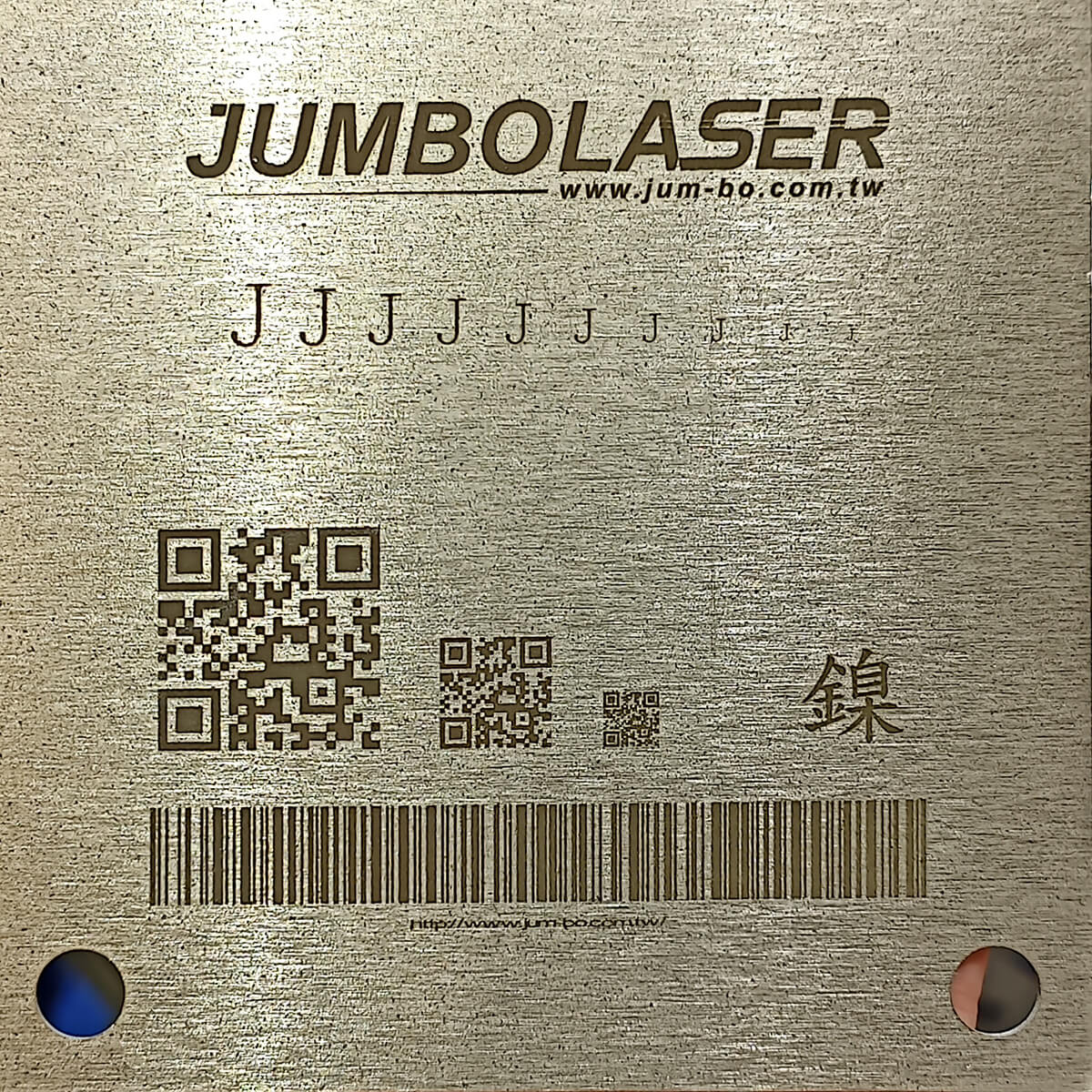

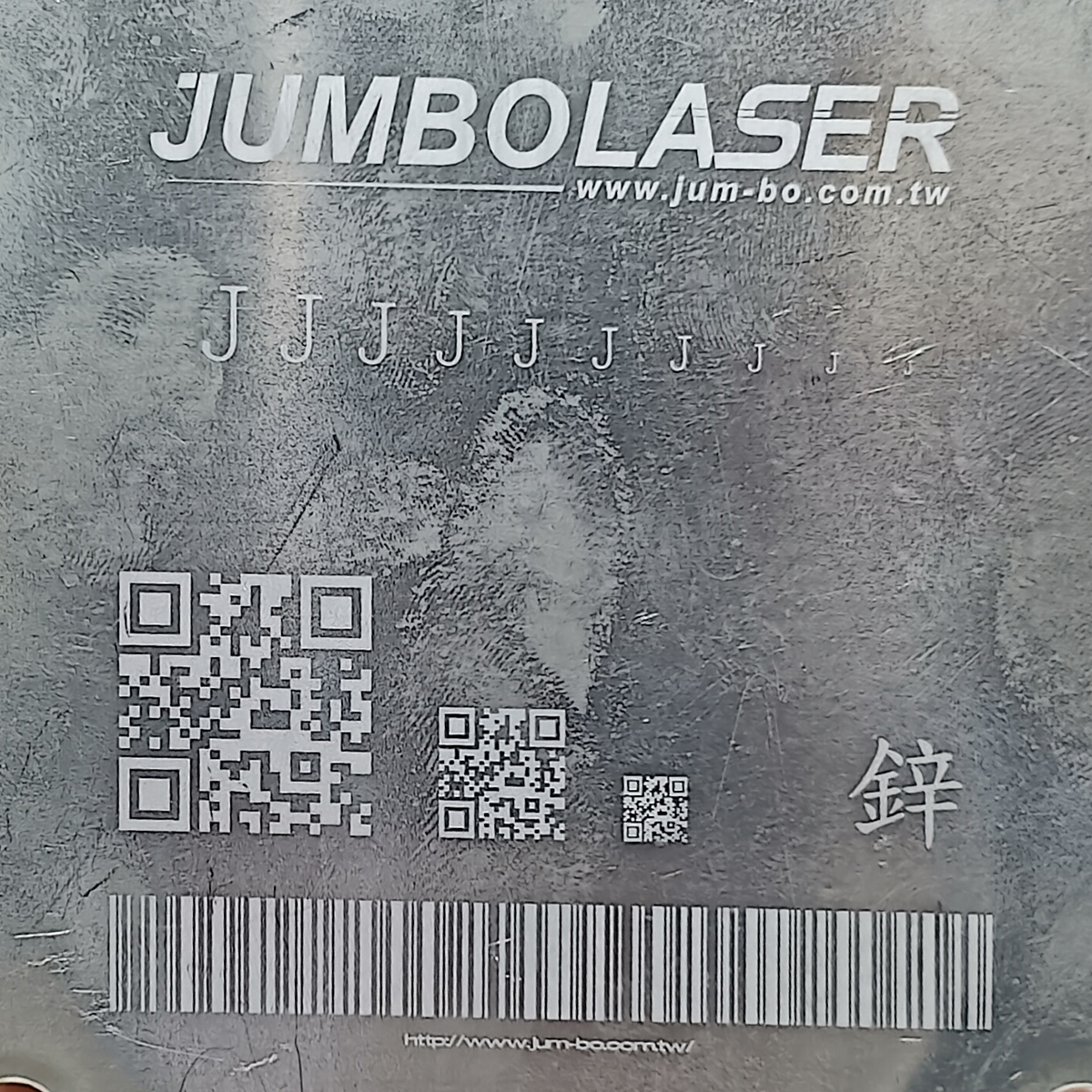

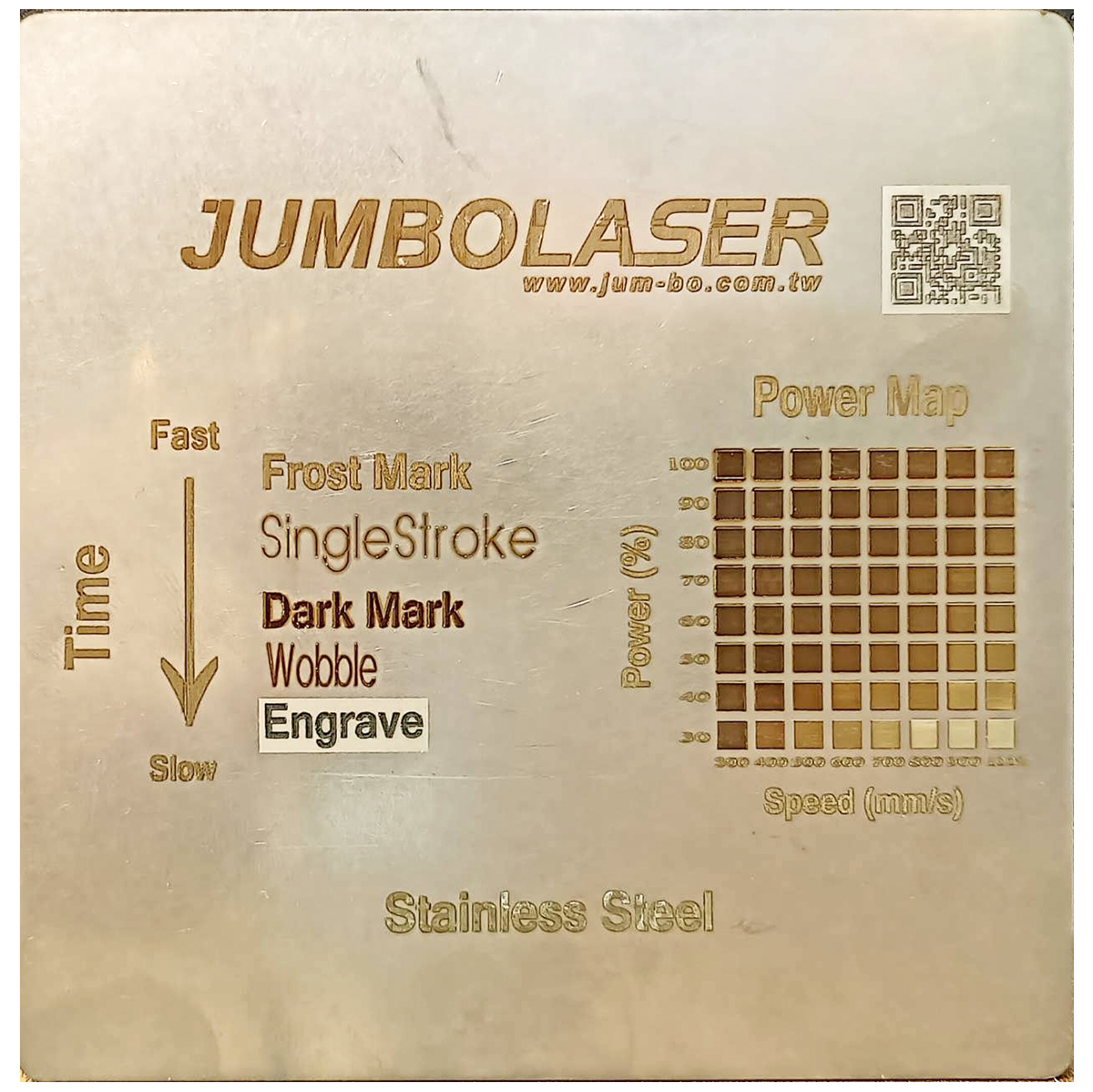

Type and thickness of materials

Desired welding depth and width

Daily or monthly production capacity requirements

Existing production line setup

Specific requirements for welding quality, precision, and efficiency

Budget range

Based on this information, Jumbo professional team will recommend the most suitable equipment and configuration for you.