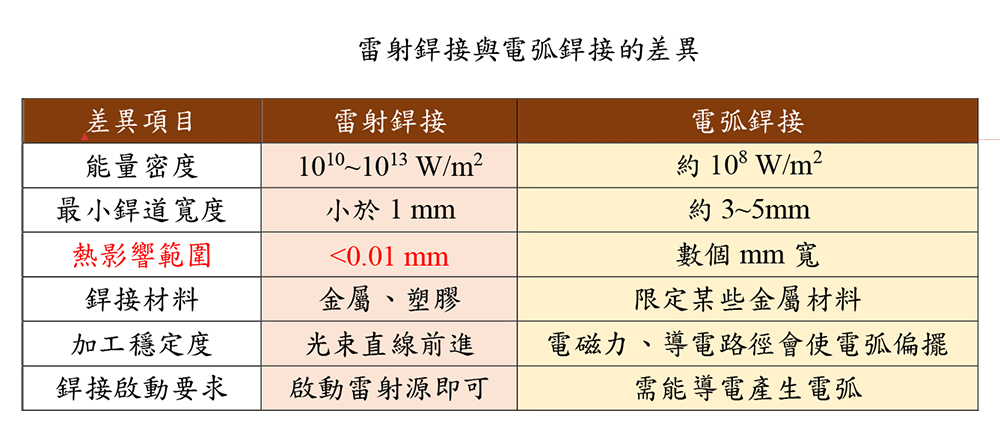

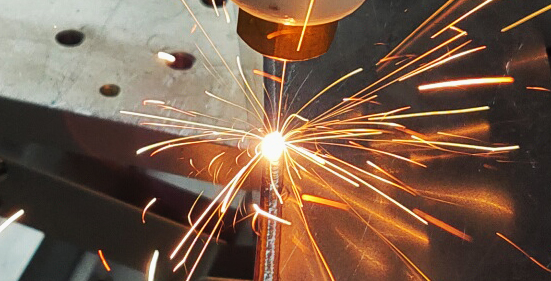

Welding is an indispensable process in industrial production. How to accelerate welding speed while achieving high quality and low distortion has always been the goal pursued by manufacturers. Although arc welding has been widely used in manufacturing, post-welding distortion and heat-affected zone softening are unavoidable side effects. However, many industrial products require precise part processing or joining, where arc welding cannot meet the demand.

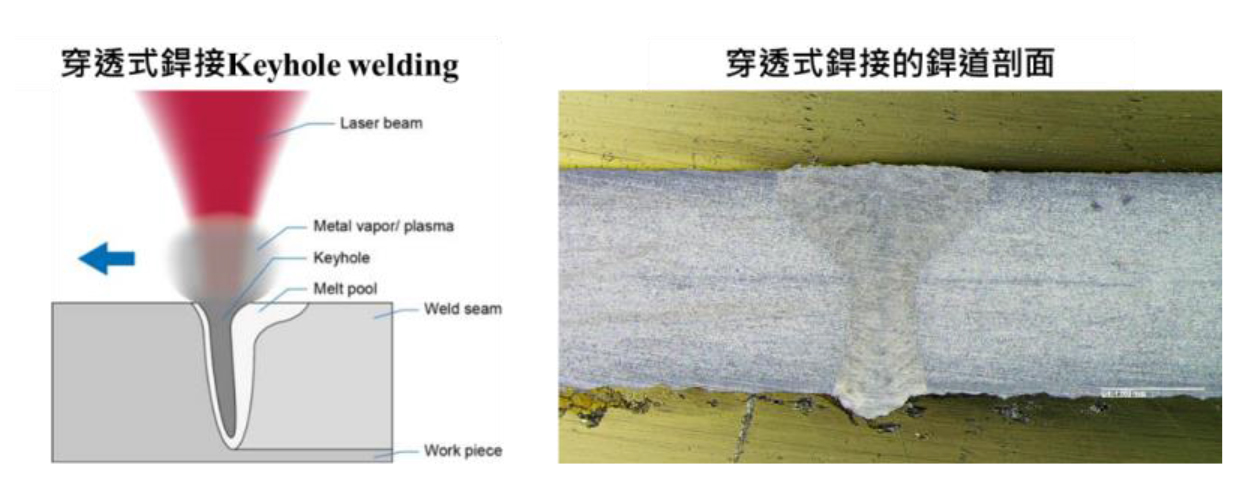

Unlike arc welding, laser welding concentrates a high-energy beam into a very small spot on the material, causing instant melting for joining. Therefore, laser welding can achieve effects that arc welding cannot, such as the keyhole welding shown below that penetrates through the entire steel plate.

These characteristics give laser welding the advantages of:

Due to the speed and excellent welding quality of laser welding, as well as the precision of laser beam positioning, it is suitable as a solution for automated welding. Therefore, laser welding has become irreplaceably important in the automotive, hand tools, hardware, electronics, and energy industries.