With the breakthroughs in generative AI, AI has become one of the hottest global industrial topics. Industries are upgrading from digitalization to AI-driven processes. In response, the Industrial & Commercial Times will host the "2024 Taichung AI Machine Tool and Automation Exhibition" from October 4–7, providing a premier platform for showcasing machine tools, precision machinery, and automation technologies. During the exhibition, the "Low-Carbon Net Zero x Smart Transformation Forum" will feature key speakers including Professor Wen-Yu Jue of National Taiwan University’s Department of Mechanical Engineering, DMG MORI, SYNTEC Group's Jumbo Laser, and other global leaders in smart automation. The forum will provide valuable insights and strategies on critical trends to guide manufacturers toward digital upgrades and enhanced competitiveness.

As a leader in laser processing, atmospheric plasma, and automation system integration, Jumbo Laser continues to drive the trend of intelligent and low-carbon manufacturing. At the upcoming forum, it will present its application technologies in micro-processing and decarbonized processes across new energy, automotive components, metal manufacturing, and medical equipment sectors.

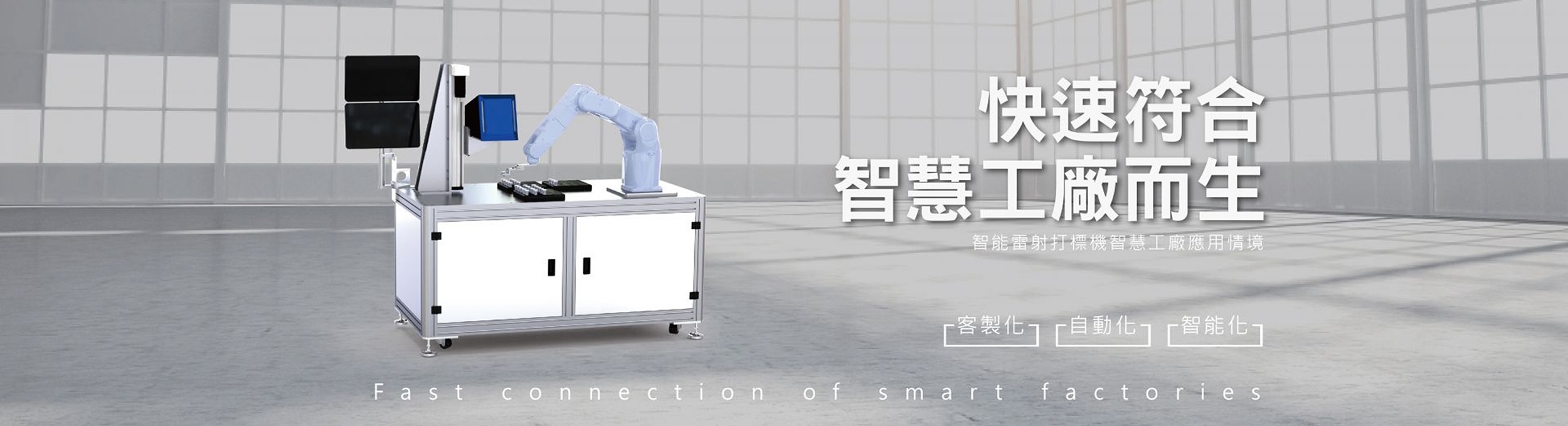

Among its featured technologies, the laser marking production traceability system has become indispensable in modern manufacturing—especially for automotive parts. Unlike traditional labeling and printing, laser marking eliminates ink usage and is more environmentally friendly. Jumbo Laser's smart laser marking machine includes automatic grading and inspection functions, ensuring the accuracy and readability of markings, significantly boosting productivity and quality control, and making it the ideal choice for low-carbon traceability.

With the rapid growth of high-tech sectors like electric vehicles, the need for welding high-reflective materials such as copper continues to rise. Jumbo Laser’s blue laser welding technology, designed specifically for these materials, is widely used in EV motor copper wire welding, ultra-thin copper heat pipes, and new energy battery power systems. It offers high efficiency, precision, and stability, with less thermal impact than traditional welding methods—making it more environmentally friendly.

Backed by extensive experience in automation integration, Jumbo Laser not only enables single-station automation but also supports full-factory and full-line automation. This significantly enhances production efficiency, reduces labor costs, minimizes human errors, and improves product consistency and stability.

Committed to technological innovation and industrial upgrading, Jumbo Laser delivers professional, intelligent solutions in laser processing, atmospheric plasma, and automation system integration—empowering the advancement of smart, low-carbon manufacturing.

The forum will continue to release featured topics, including: Professor Wen-Yu Jue of NTU presenting "Applications and Development Trends of Smart Machinery"; DMG MORI discussing the topic of "Circular Economy"; and a global leader in smart automation sharing insights on "Smart Factories and Automated Storage Solutions." Registration is welcome.

News source: https://www.ctee.com.tw/news/20240728700707-431203