LNC's smart cloud solution, SynFactory, empowers factories through data-driven transformation. It offers function modules designed for various stakeholders, enabling data collection via equipment IoT, standardization of biotechnical process data, and real-time reporting feedback. It integrates all edge-to-cloud functional modules to build customized dashboard control centers, including OEE performance metrics, plant production status, and personnel performance displays. Factory managers can monitor real-time production remotely using a computer—or even a smartphone—achieving intelligent factory management on the go.

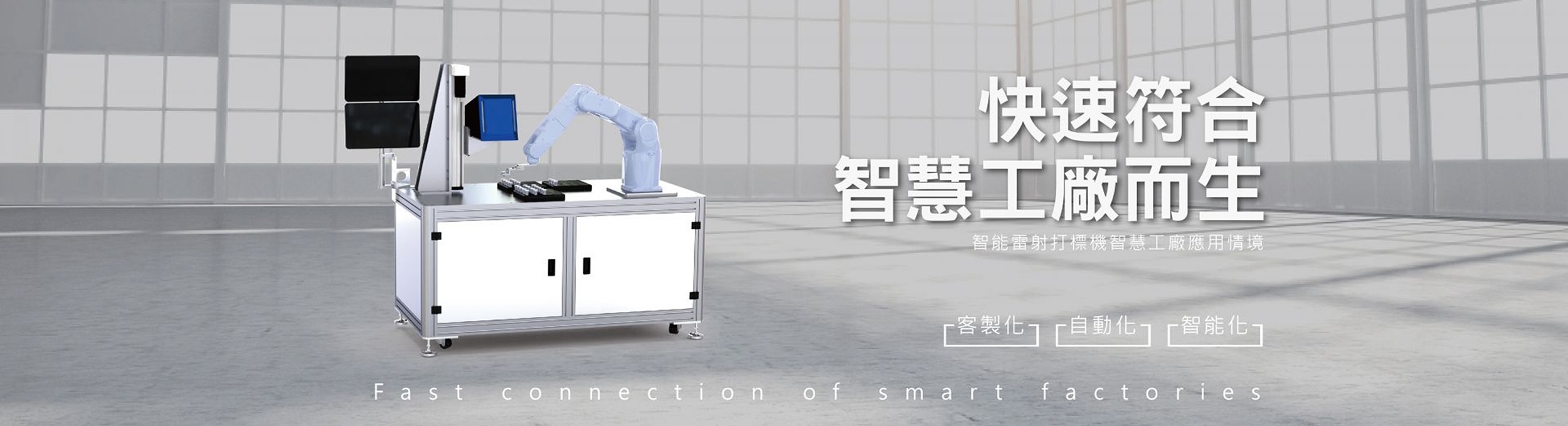

LNC's flexible AMR (autonomous mobile robot) units feature modular and mobile designs for fast deployment, line changeovers, and quick adaptation, making them ideal for small-batch, high-variety production scenarios. Compared to traditional robotic pick-and-place systems, this setup shortens line change time by 94%, reduces labor costs by 66%, and increases equipment utilization by 76%, enabling uninterrupted, cost-efficient, and flexible production. At the expo, the demo integrates Jetlasers' laser marking solution, where a rotary indexing table allows simultaneous loading/unloading and marking, reducing cycle time and freeing operators for high-value tasks.

At this year's Hardware & Tools Expo, Syntec Group positions itself as the equipment management expert for the metalworking industry. Through consultative guidance and modular solutions, it makes dual-axis transformation as simple as stacking building blocks, helping manufacturers kickstart smart and automated factories with ease.

Source: Economic Daily News https://money.udn.com/money/story/5640/7481837