Caption: SYNTEC positions itself as the most trusted smart manufacturing partner, showcasing integrated automation solutions for digital transformation and carbon reduction alongside LEANTEC and JUMP LASER.

Caption: SYNTEC positions itself as the most trusted smart manufacturing partner, showcasing integrated automation solutions for digital transformation and carbon reduction alongside LEANTEC and JUMP LASER.

Founded nearly 30 years ago, SYNTEC has become a leading CNC controller manufacturer in Asia. Initially focusing on direct sales to machine tool manufacturers, years of market experience allowed the company to hear the voices of end-user factories who sought more than just controllers — they sought automation and digital transformation.

Responding to customer needs, founder Kevin Tsai established LEANTEC in 2018 to develop smart manufacturing solutions, including industrial robots, machine networking, and automation systems, promoting industry upgrades.

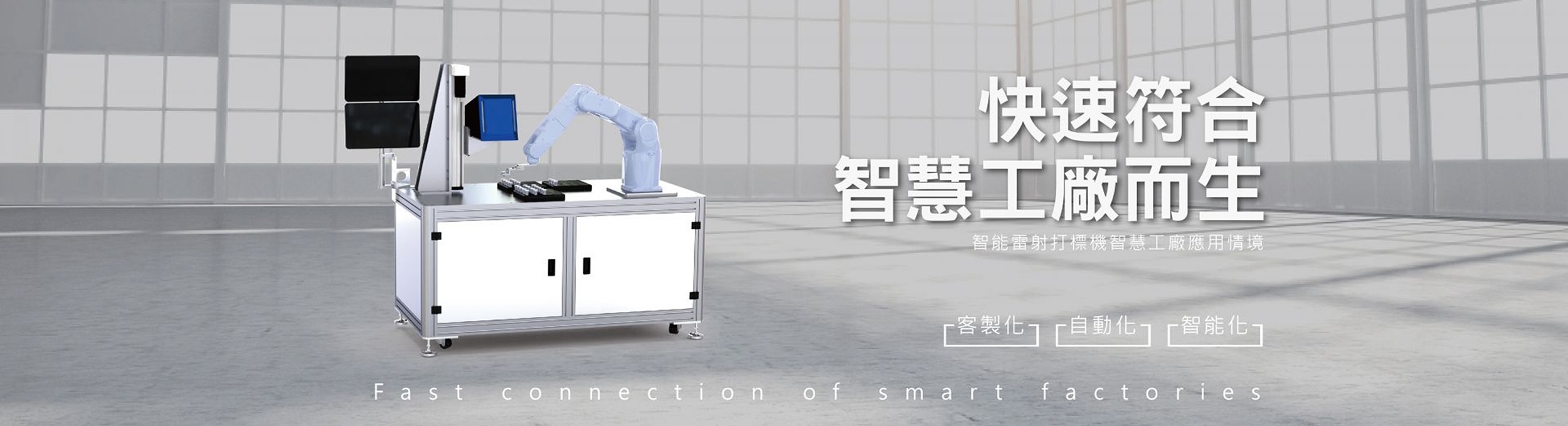

At the 2024 Taipei Automation Show, SYNTEC and LEANTEC showcased robotic arms integrated with central control systems — not merely selling robots, but offering full-scale solutions tailored to different automation demands. These systems smartly reduce machine tool idle times, boost productivity, and lower costs.

Modular Approach to Solve Urgent Customer Needs

SYNTEC Group presented a smart metalworking factory example using its cloud software to connect machines and robots, uploading data to a cloud war room as a management platform.

This allows executives to view real-time production and utilization data remotely via mobile app, taking the first step toward factory digital transformation.

To ensure ROI on digital investments, SYNTEC launched the Smart Production Cloud with over ten function modules such as scheduling, inspection, maintenance, and inventory. With LEANTEC’s consulting service, clients can implement modules based on urgency and specific pain points.

Beyond standalone smart tools, LEANTEC’s smart cell and cloud products enable AI implementation. Each smart unit (Cell) includes a visual data dashboard, allowing on-site data monitoring without waiting for line-end reports.

JUMP LASER, a SYNTEC Group company, showcased its award-winning Intelligent Laser Marking Machine at the event, along with micro laser processing and blue laser welding systems. These technologies serve industries such as metalworking, electronics, automotive, and semiconductors to support low-carbon production.

As sustainability and carbon reduction gain global traction, laser processing is gaining attention for its energy-saving and low-pollution advantages.

Take CSC (China Steel Corporation) for example — they previously used inkjet printing for coil numbering, which caused issues for TOYOTA supplier Kuozui Motors. Printed coils required trimming before use. Every year, CSC recycled these offcuts for re-smelting. Now, with JUMP LASER’s technology, numbering is done with laser directly on steel strips. This saves CSC tens of millions in costs and over 1,000 tons in carbon emissions annually — a benchmark in carbon reduction and ESG achievement.

Founded in 1995, SYNTEC Group has dedicated itself to developing software and hardware technologies for machine tools and automation controllers. Today, it’s one of Asia-Pacific’s top brands, holding over 250 patents and maintaining over 60 global service locations. In 2023, it established an APAC operations center in Selangor, Malaysia. This year, SYNTEC expanded with a new Malaysian plant, inaugurated by Director Angie Huang in July, to serve customers across Thailand, Vietnam, Singapore, and India.

On the financial front, SYNTEC posted impressive results in the first half of 2024, with revenue surpassing 70% of the total from 2023. EPS hit NT$13.35, already exceeding last year’s NT$10.85.

Smart Manufacturing ESG Sustainability