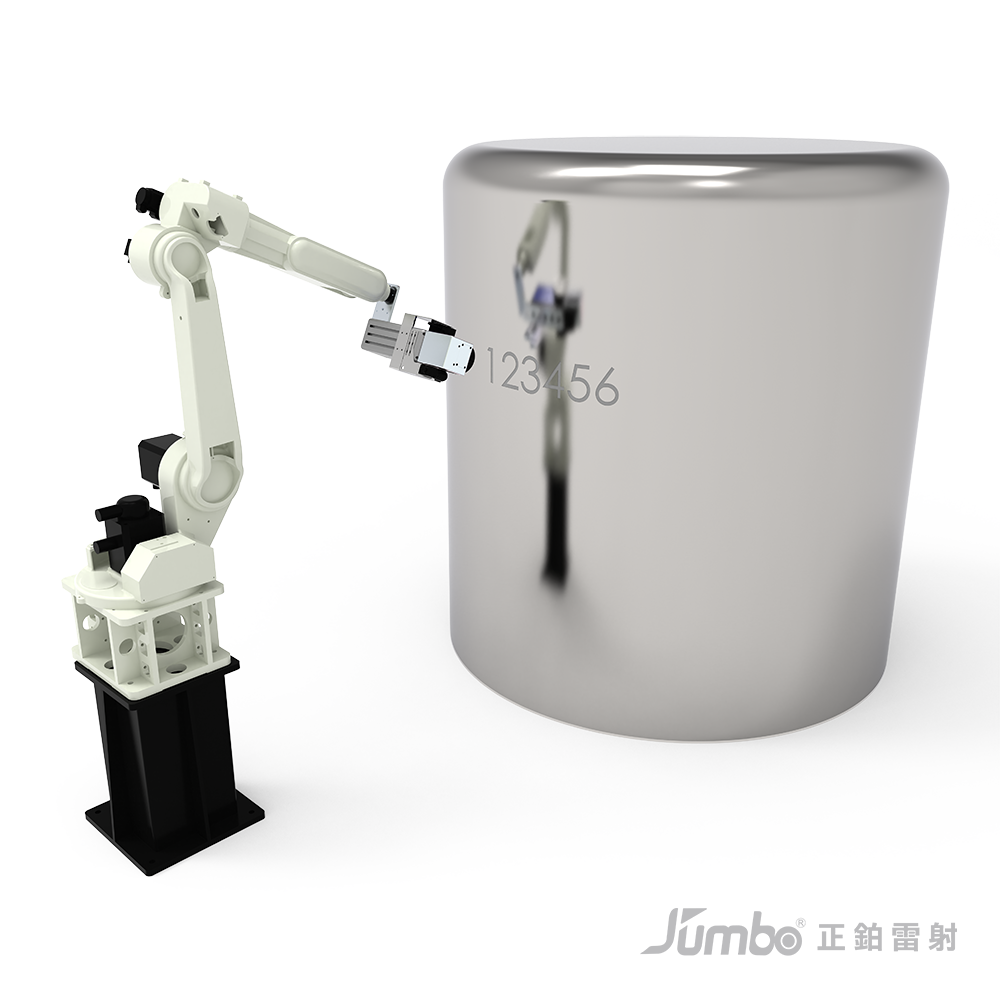

A well-known Taiwanese fluid component manufacturer recently successfully introduced an intelligent laser marking machine combined with a dual-layer trolley robot to achieve production automation, generating significant economic benefits. To comply with the requirement that key parts must have production traceability barcodes, the company must follow international barcode standards verified at Grade B or above. Originally, laser marking machines and barcode quality stations were set up at the post-production process to ensure product quality.

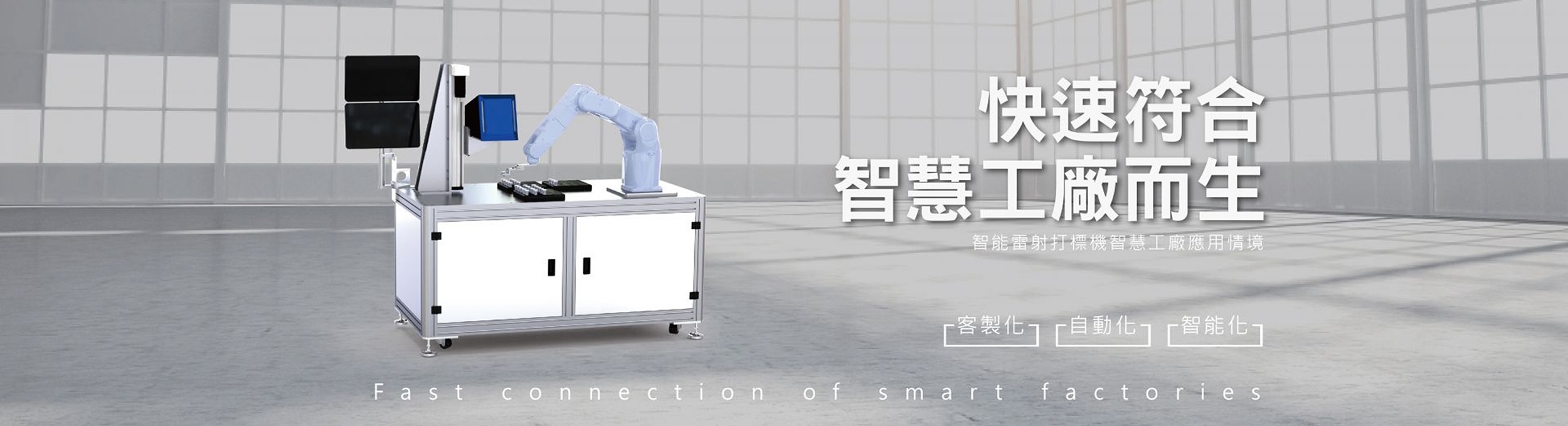

As labor costs continue to rise, the manufacturer actively sought automation solutions. After detailed investigation and evaluation, an intelligent laser marking machine with post-marking quality inspection capability became their top choice. Combined with robotic arms, automated production was achieved, greatly improving production efficiency.